Fluororesin Coating

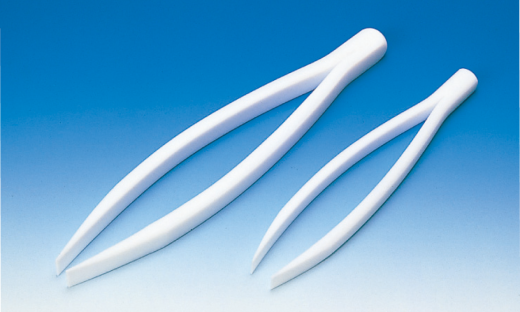

We are introducing containers, cork, spoon, tweezers, shovel, brush, pump, gasket, O ring, sheet, tube that are made of the material like PTFE, PFA, FEP, ETFE.

Some products are coated on the surface to get excellent properties of fluororesin.

Fluororesin coating is a technology that imparts the excellent properties of fluororesin, such as heat and cold resistance, chemical and corrosion resistance, non-stick properties, low friction characteristics, electrical properties, and non-flammability, to the surface of materials such as metals, ceramics, and glass.

The type of fluororesin used for the coating varies depending on the application, and the processing method also changes accordingly. Generally, the process involves physical surface treatment of the substrate (such as roughening by sandblasting), coating (liquid coating or electrostatic powder coating), drying, firing, and cooling in sequence.

The thickness of the coating film also varies depending on the type of coating material, with a single process layer being approximately 20 to 200 micrometers thick. By repeating the coating and heat fusion process, it is possible to apply thicker coatings.

*Quoted:Fluororesin Product Catalogue Vol.105