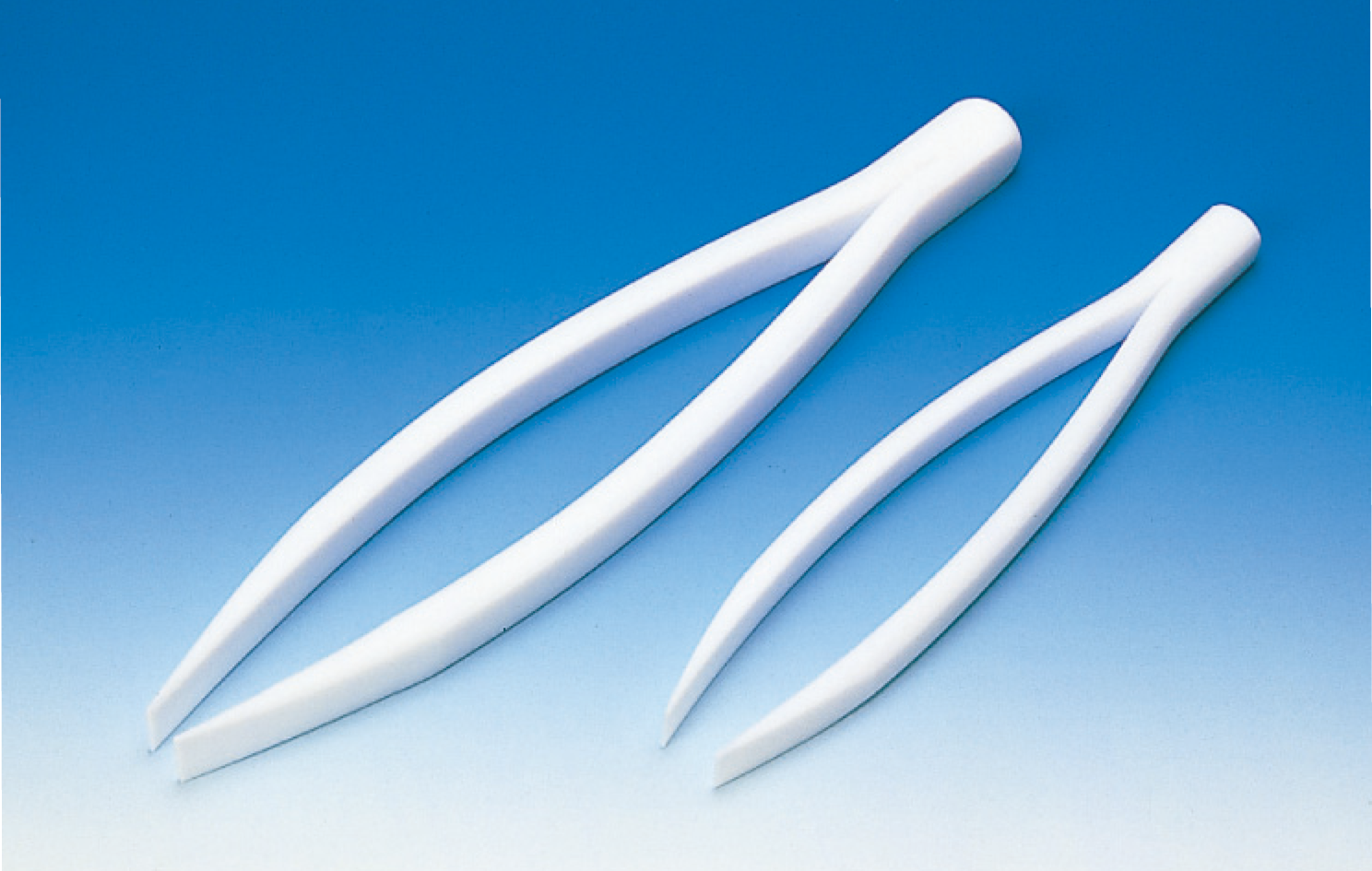

Fluororesin products made by machining

We are introducing container, cork, spoon, tweezers, shovel, brush, pump, gasket, O ring, sheet, tube that are made of the material like PTFE, PFA, FEP, ETFE.

The products are precisely finished by machining.

“Machining” refers to a process where materials are cut with a blade to achieve the desired dimensions and shapes. Machining allows for the creation of a wide variety of shapes, making it possible to produce complex experimental devices. While mass production of products is suitable for injection molding using molds, the initial cost of creating molds for fluororesin is very high. Therefore, machining is more suitable for small-scale production.

Machining is broadly divided into two types: lathe machining and milling.

- Lathe Machining: The material is rotated while the cutting tool is fixed to perform the cutting.

- Milling: The material is fixed while the cutting tool rotates to perform the cutting.

With lathe machining, the material is rotated, making it suitable for processing cylindrical shapes. With milling, the cutting tool rotates, allowing for any shape to be processed depending on how the tool is moved. Typically, lathe machining is more efficient, and designing products as rotational bodies can be more cost-effective. Many of our catalog products, such as fittings and valves, are manufactured using this machining process. The items listed in the catalog represent only a portion of what we can produce.

We continuously receive consultations for custom-made products from our customers, and we manufacture fluororesin products that are not standard catalog items.

*Quoted:Fluororesin Product Catalogue Vol.105